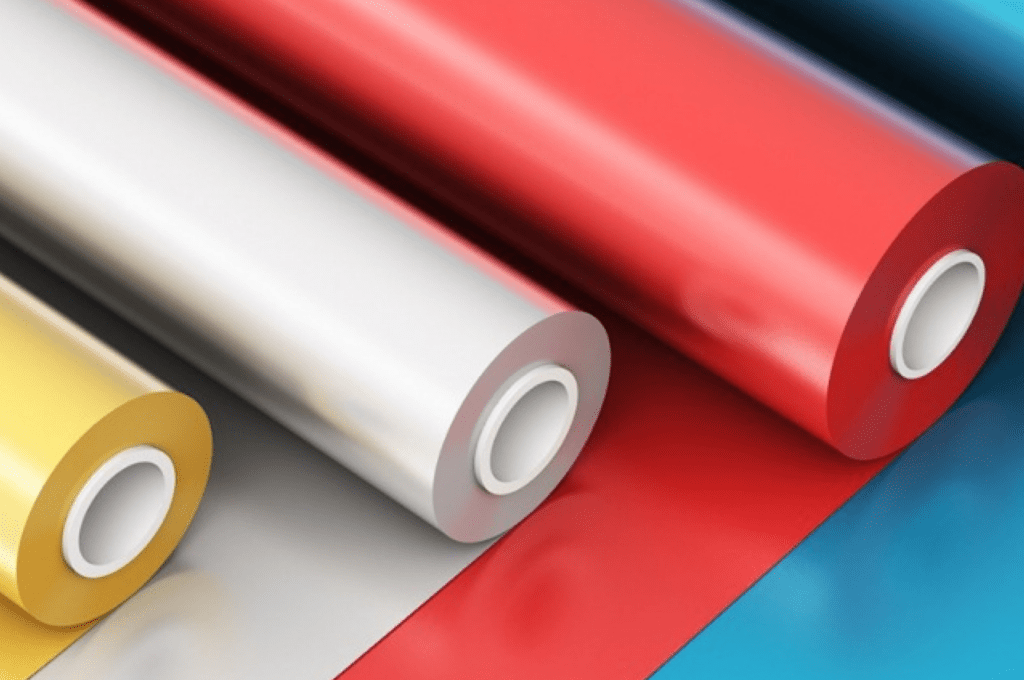

TPU

BULLETPROOF FILM

TPU FILMS MAINLY COMPOSED PF POLYURETHANE ELASTOMER, WHICH IS MADE BY SPECIAL PROCESS

Product Features And Advantages

*Low Temperature Resistance

The performance remains unchanged in the extreme low temperature environment of minus 60°C.

*Excellent adhesive performance

- It can bond different materials TPU laminated film not only has superior adhesion with inorganic glass and ceramics, but also has excellent adhesion performance with organic materials such as PC board, PMMA (acrylic), PETetc.

- It is an excellent choice for making composite bullet proof glass and shatterproof glass.

*Excellent Aging Resistance

- TPU has good weather resistance, anti-yellowing performance and is not easy to aging, not sensitive to water and other chemicals, no need for edge sealing.

*Excellent Resistance To Penetration

- TPU itself has good toughness and impact resistance.Using it to make laminated glass can improve the antiriot and bullet proof functions of the glass.

- It is the best choice for making high-grade bullet proof vest.

TPU Film Composite Production Tech Reference

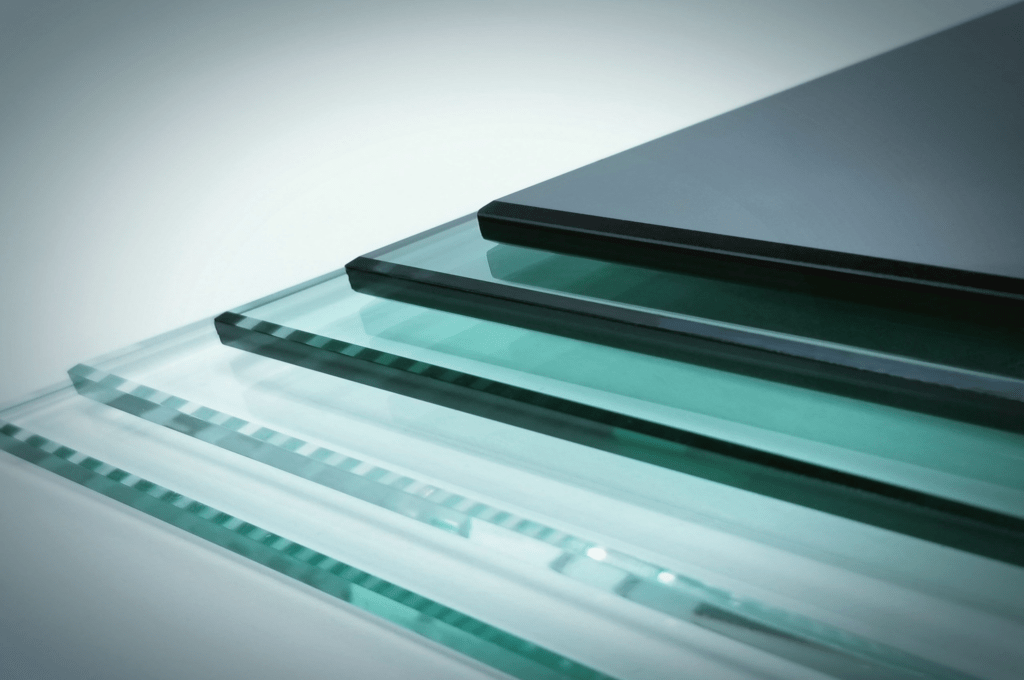

1. Laminated Glass

- Clear-Room: The temperature standard: 20-25°C; The humidity: 23%+2%; The room should be dust-free; The machines should be clean. The operators must wear uniforms, hats, gloves and keep neat.

- Lay-up sandwich conditions: The surface temp ofthe glass: 20-30°C (the max 40°C); Film surface temperature: 20-25°C; The film and glass are clean and accurately placed.

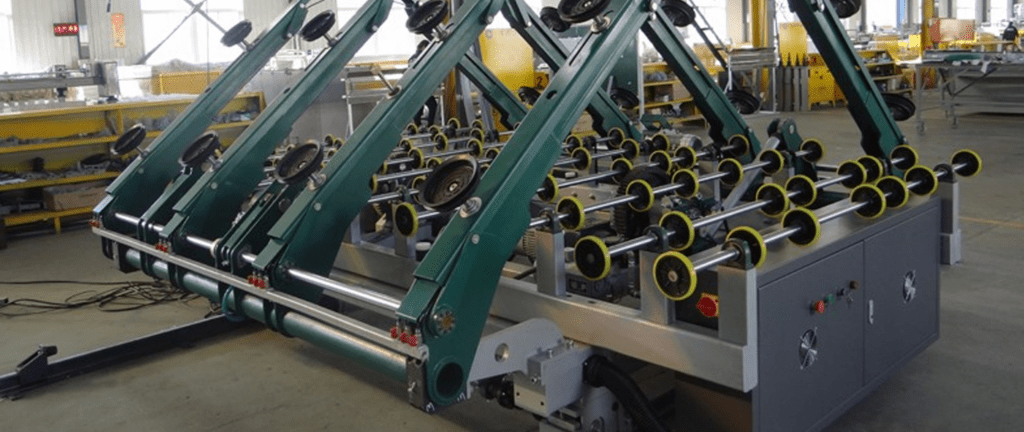

2. Pressing Section

- Cold andhot extraction:

- 1. Cold extraction: temperature 20-25°C, pressure-0.095-0.1Mpa.The continuous vacuum pumping time is about 20 minutes, and if the vacuum is not continuous, the cold pumping time is about30 minutes.

- 2. Heating extraction: The surface temperature of the glass is 100-120°C, the time is 30-45 minutes, and the pressure is between -0.095-0.1Mpa. Remove the glass when cooled to 45-60°C.

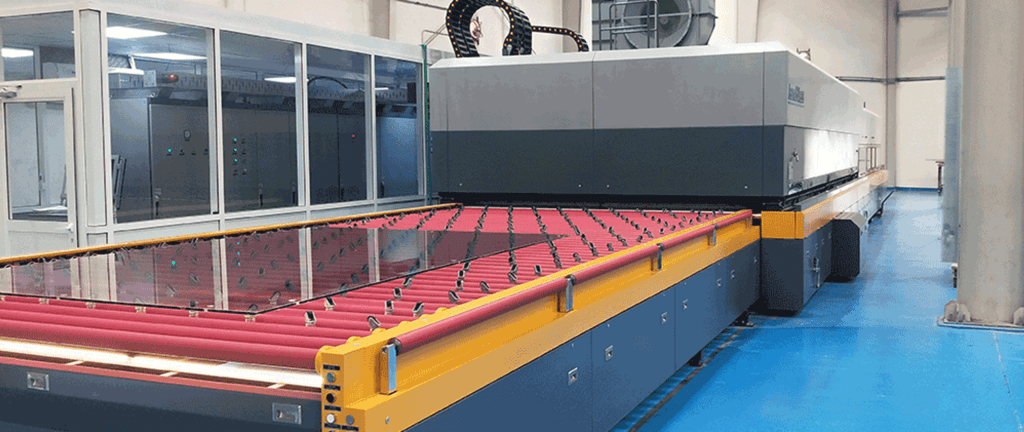

- Rolling exhaust:

- 1.

1] Preheating-Glass Surface temperature: 20-30°C, umidity: about 25%

2] First oven temperature: 100-120°C, First big niprollers pressure: 0.2-0.5Mpa, the gap of two big nip rollers shouldbe less than the total glass thickness about 1mm

3] Second oventemperaturer: 160-180°C

4] Third oventemperature: 220-240°C

5] Second big nip rollers pressure: 0.3-0.5MPa, the gap of rollersshould be less than the total thickness glass about 2mm. - 2. Maintain continuous working, and maintain ovens temperature.

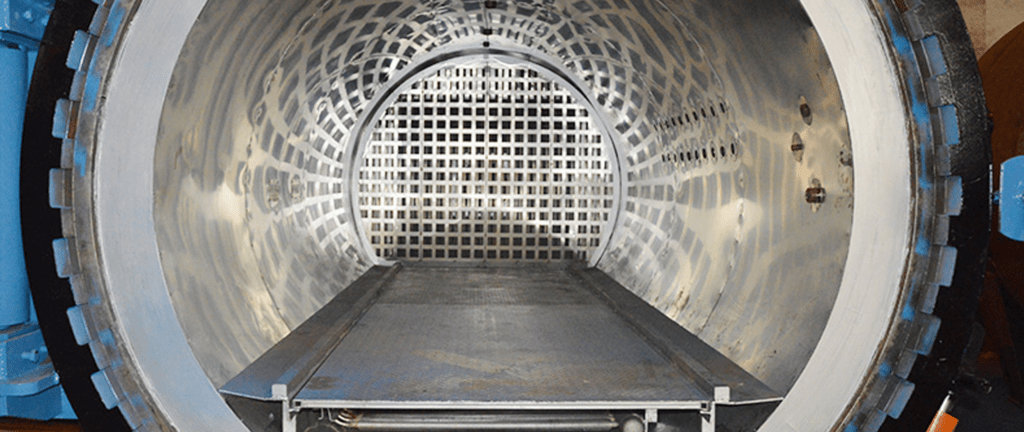

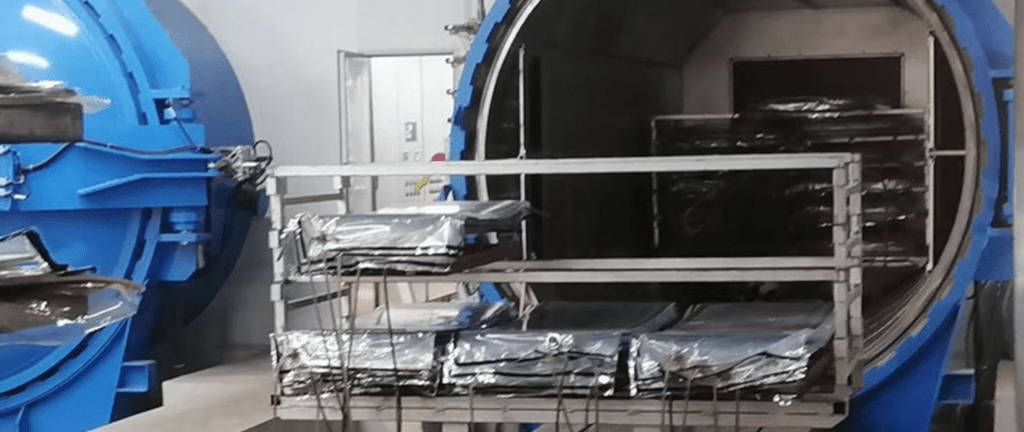

3. Autoclave Process

- Autoclave Process The whole process should be slowly working in heating, pressure, cooling and depressurized.The following process can be used as a reference:

- 1. Rising temperature and pressure increase

2. Temperat urereach to 60 °C, Pressure is 0.4Mpa

3. Temperature reach to 90°C, Pressure is 0.8Mpa

4. Temperature reach to 120-130°C, Pressure is1.0Mpa

5. Pressure reach to 1.1-1.3Mpa

6. Constant temperaturefor 30-60 minutes (depending on the thickness and quantity of glass in autoclave)

7. Constant pressure in cooling, naturally slowly cooling to 90°C Exhaust when temperature falls to 45-55°C.

Product Specifications

FLS-EU TPU Specifications and Technical Data

Thickness

Width

Length

0.38mm

800mm-2800mm

100m

0.63mm

800mm-2800mm

100m

1.25mm

800mm-2800mm

50m

Note: Non-standard size can be customized

Technical Parameter

FLS-EU TPU Technical Parameters

Testing Item

Test Result

Testing Standards

Shore Hardness

75A

ASTMD2240

Density

1.06g/cm3

ASTMD792

Transmittance

91.7%

ASTMD1003

Haze

0.23%

ASTMD1003

Tensile Strength

45MPa

ASTMD638

Tear Strength

75.2KN/M

ASTMD1004

Elongation At Break

530%

ASTMD638

Peeling Strength

18.6KN/M

ASTMDD3330M

Glass Transition Temp.

-60°C

ASTMDD3418

Vergilbungsindex

0.2

ASTMDE313

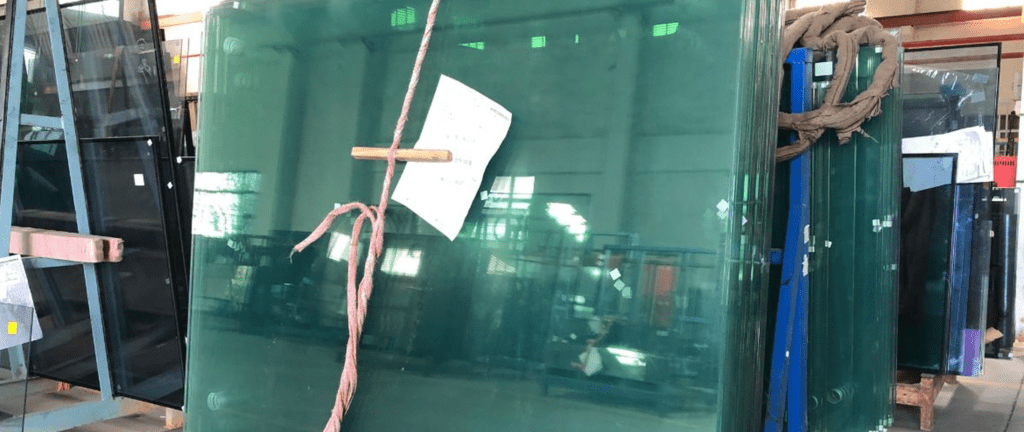

TPU Application Cases

Explosion Proof | Bulletproof

Armored Glass, Bulletproofglass, and Shatterproofglass

Composite Materials

TPU can be applied to various material protection

Special Windshield Glass Project

High-speed Trains and Aircraft TPU film provided by our company, perfect through the bird impact test, extreme low temperature impact test.

Chow Tai Fook Shanghai Flagship Store Project

Shanghai Jewelry store project Adopt our 0.63mm TPU composite PC board, anti-smash grade reached C.

Brazilian Presidential Palace Project

Brazilian Presidential Palace Project Adopt our 1.25mm TPU multilayer composite PC board, bulletproof level reaches NATO level 2.

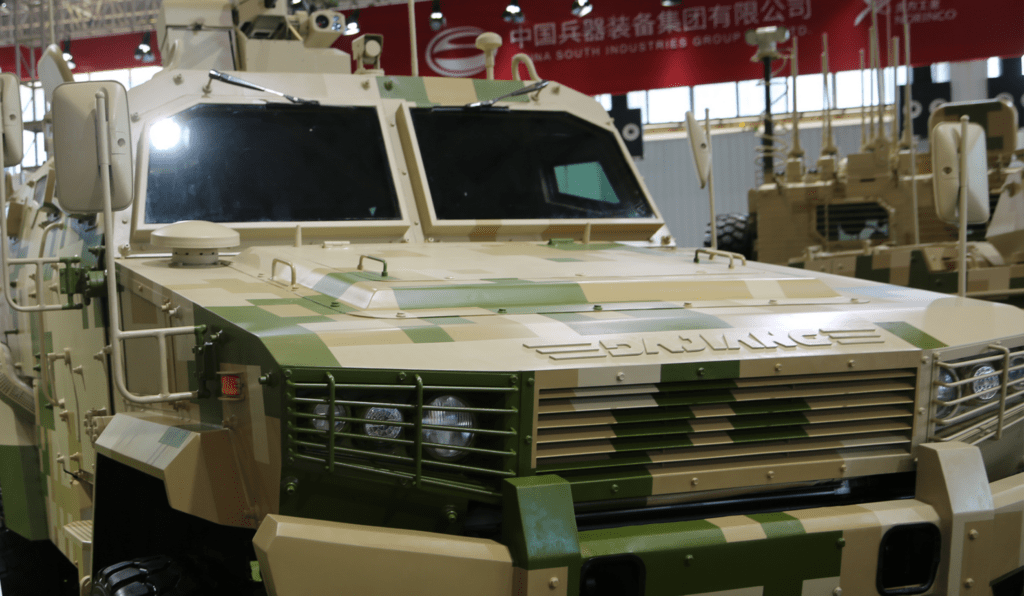

Military Bulletproof Glass Project

Armored Vehicles Using our TPU composite PC board, bulletproof-level: FJ79B, weight and thicknessis only 1/2 of the traditional bulletproof glass.

Contact

Chief Executive Officer

Mr. An Sun

Mettmanner Str. 51

40699 Erkrath

Deutschland

Phone: +49 176 845 868 46

Email:

an.sun@fls-eu.com

Sales Director

Ms. Dussling Jiang

Mettmanner Str. 51

40699 Erkrath

Deutschland

Phone: +49 157 378 581 25

Email:

xiao.jiang@fls-eu.com