PVB

INTERLAYER FILM

PVB IS A BONDING MATERIAL USED IN THE MANUFACTURING OF LAMINATED GLASS. THIS PRODUCT A PVB FILM WITH INSULATION FUNCTION BY ADDING NANO I.M TO PVB

Product Features And Advantages

*Rich in color, diverse in variety

- Our company produces various types of color PVB films, including domestic and export color schemes.

- Including; porcelain white, milk white, matte, green, ocean blue, brown, gray, blue star gray, European gray, and so on.

*Excellent chemical propers

- Transparent, heat resistant, cold resistant, moisture resistant, and high mechani- cal strength PVB interlayer film is a semi transparent film made of polyvinyl butyral resin plasticized and extruded into a polymer material.

- The appearance is a semi transparent film, free of impurities, with a flat surface, a certain roughness and good softness, and has good adhesion to inorganic glass.

*Outstanding physical properties

PVB interlayer film is currently one of the best adhesive materials for manufacturing laminated and safety glass in the world, with the performance of safety, anti-theft, explosion-proof, sound insulation, and energy saving.

*Outstanding physical properties

- PVB interlayer film is currently one of the best adhesive materials for manufacturing laminated and safety glass in the world, with the performance of safety, anti-theft, explosion-proof, sound insulation, and energy saving. polymer material.

PVB Film Production Proces

1. Laminated Glass

- Lamination Room: Temperature should be 20-25°C, below at 30%, Dust proof and keep the machine clean and tidy, workers need to keep uniform, cap and grove clean in order to avoid the adhesion of dust, impurities and hair.

- Conditions: The temperature of lamination is suggested to be 20-30°C, the highest temperature should be no more than 40°C. temperature of PVB suggested to be 20-25°C. PVB film and glass need to be checked several times if they are clean and matched or not.

2. Process of Pre-Pressing

- Cold Drawing: Temperature: 20-25°C Stress:-0.095-0.1mpa.2-

15minutes in the continuously cool drawing. - Heat Drawing: Temperature of glass should be 100-120°C, 30-45minutes, Stress between -0.095–0.1mpa, take out the glass when temperature rise up to.

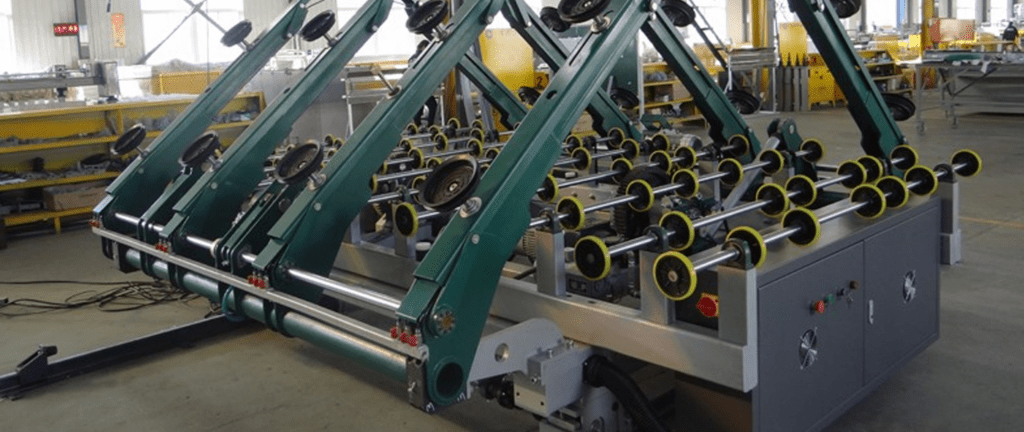

3. Process of Rolling Method

- Thermostat pre-heating the lamination glass temperature is 20-30°C, humidity of 25% first temperature 100-120°C, first roller, pressure is 0.2-0.5mpa, the roller distance should be less than 1mm of laminates glass thickness.

- Second thermostat temperature 160-180℃. third thermostat temperature 220-240°C.

- second roller, pressure 0.3-0.5mpa, the roller distance should be less than 2mm of laminated glass.

- Keep the thermostat temperature by continuous work.

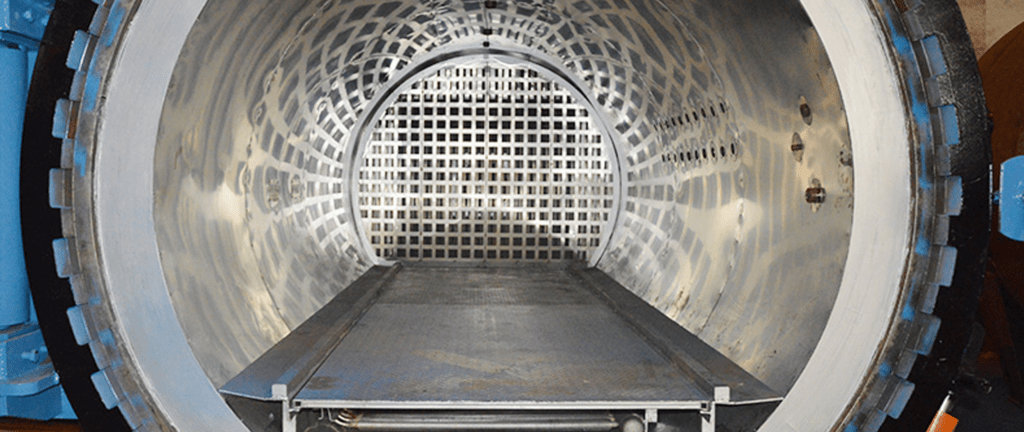

4. High Pressure Formation

- The temperature and pressure should be risen or slow down at low speed during the whole procedure. As reference following:

- 1. Raise the temperature and pressure-up to 60°C, pressure to 0.4mpa.

- 2. Temperature to 90°℃, pressure to 0.8mpa.

- 3. Temperature to 120-130°C, pressure to 0.1mpa-pressure to 1.1-1.13mpa.

- 4. Keep temperature 30-60 minutes (depend on the glass thickness and quality in the autoclave.

- 5. keep the temperature down to 90°C with the stable pressure. Exhausting with temperature down to 45-55°C.

Product Specifications

FLS-EU PVB Film Product Specifications [Rolls]

Thickness

Width

Length

0.38mm

500mm-3600mm

400m

0.76mm

500mm-3600mm

200m

1.14mm

500mm-3600mm

150m

1.52mm

500mm-3600mm

100m

Note: Other non-standard size can be customized according to customer

Technical Parameter

FLS-EU PVB Technical Parameters

Catagory

Parameters

0.38mm

0.76mm

1.52mm

Length Tolerance

+[0-5.0]

+[0-2.0]

+[0-1.0]

Width Tolerance

+[0-15.0]

+[0-15.0]

+[0-15.0]

Tolerance

±0.02

±0.03

±0.05

Moisture Content

≤0.5%

≤0.5%

≤0.5%

Tensile Strength

≥20.0

≥20.0

≥20.0

Building Haze

<0.4

<1.5

<2.0

Automotive Haze

<0.6

<0.8

/

Shrinkage Rate

<10.0

<10.0

<10.0

Shrinkage Rate

≥88.0

≥85.0

≥85.0

Elongation At Break

≥200.0

≥200.0

≥200.0

Yellowing Index

≥8.0

≥8.0

≥8.0

Resistivity [Ω*1011]

≥2.0

≥2.0

≥2.0

Shrinkage Rate - 60°C/15min

Contact

Chief Executive Officer

Mr. An Sun

Mettmanner Str. 51

40699 Erkrath

Deutschland

Phone: +49 176 845 868 46

Email:

an.sun@fls-eu.com

Sales Director

Ms. Dussling Jiang

Mettmanner Str. 51

40699 Erkrath

Deutschland

Phone: +49 157 378 581 25

Email:

xiao.jiang@fls-eu.com