SGP

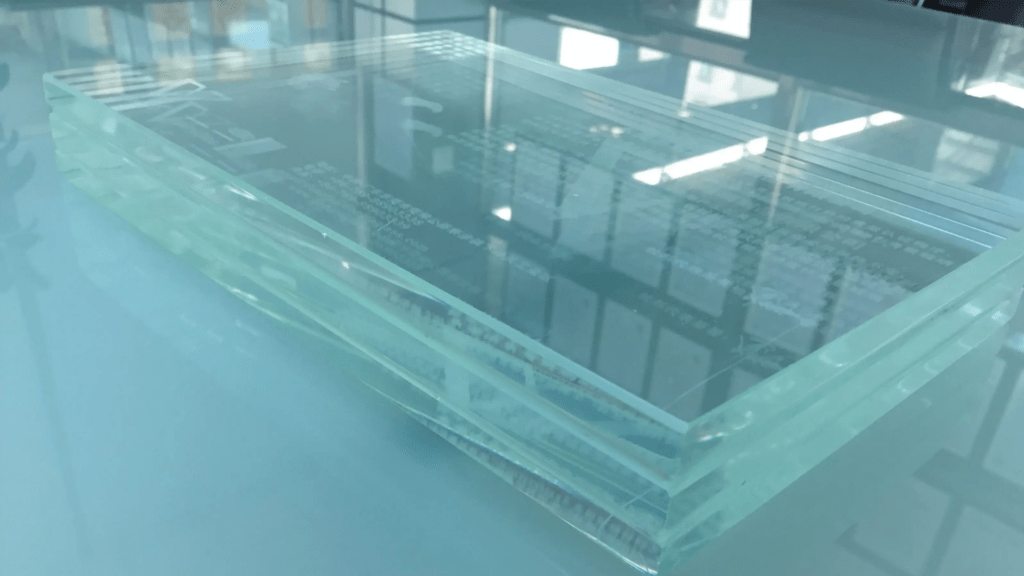

IONIC INTERLAYER FILM

SGP interlayer film is a nwe type of polymer material with high molecular weight and high elastic modulus, which is bondede by ion bonds.

Product Features And Advantages

*Possesses High Tensile strength

- With superior strength and shear modulus,excellent mechanical properties.

- The shear modulus of SGP is 100 times that of PVB and the tear strength is 5 times that of PVB.

- The bearing capacity of SGP laminated glass is 2 times that of PVB laminated glass of equal thickness.

- Under the same load and thickness, the bending deflection of SGP laminated glass is only 1/4 of that of PVB laminated glass.

*Excellent edge stability

- It has great edge stability and can be used with open edge. Side stability refers to the durability of the side of laminated glass exposed to outside conditions.

- PVB adhesive is not resistant tomoisture, easy to unglue and separate under the action of water vapor, requiring the edge treatment.

- SGP flm has excellent side stability, not sensitive to moisture, low hygroscopiness, in the exposed conditions will not be used in ungluing, separation, you can use in edge opening, without edge sealing.

*Superior weather Aging resistance

- Excellent weather resistance and less prone to aging.

- After years of aging tracking periments by authoritative institutions, there have been no obvious bubbles or yellowing imagination after 20 years.

*High-strength safety performance

- Excellent post-crushing safety and anti-intrusion performance SGP interfilm laminated glass has excellent integrity and can bond broken glass to form a strength structure after damage.

- Its bendingde for mation is tiny, and it can bear a certain amount of load without falling the whole piece.

- This greatly improves the safety of glass.

*Colorless and transparent

- Colorless and transparent.not easy to shift color,excellent permeability, yellowing index less than 1.5 excellent weather resistance.

*Excellent bonding performance with metals

- Excellent bonding with metal. SGP has superior bonding strength with metals, such as aluminum, steel and copper.

- The laminated glass made of SGP and wire, mesh and plate can considerably improvethe performance of glass after breaking, and has strong anti.

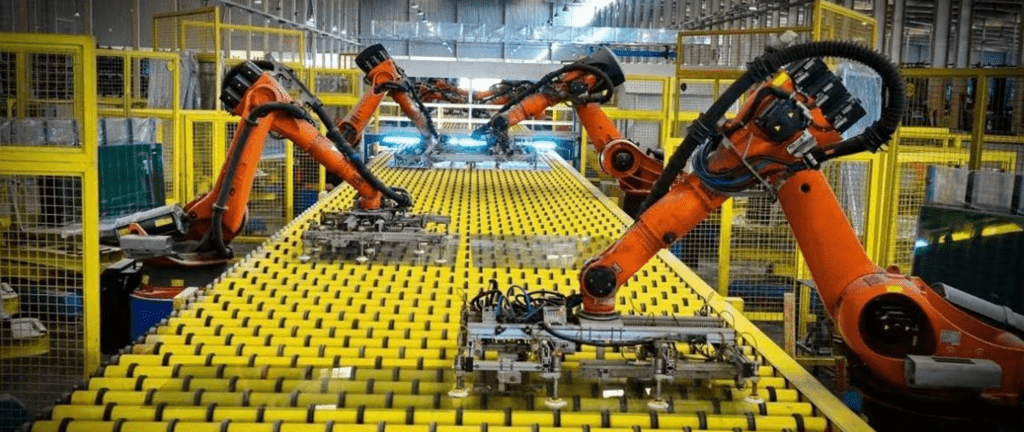

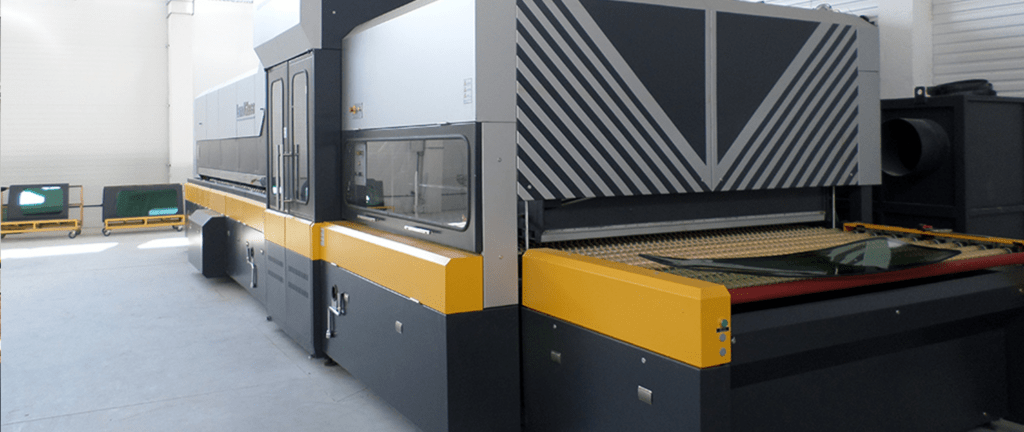

SGP Laminated Glass Production Process

1. Pre-processing and cutting of SGP film before laminating

- Pretreatment of SGP film before lamination: Use a sharp knife to cut the SGP.

- Before using the SCP film, dry it with ionized clean air andwipe it with a dust-free cloth. Usually, it is not recommended to use a cleaning machine.

- However, if a cleaning machine must be used because there are too numerous stains on the surface, still do not use detergent. Instead, use deionized water with a temperature no higher than 38° C.

- The adhesion between the glass cleaned with deionized water and the SGP film is higher than that of the glass cleaned with tap water.

2. Laminated Glass

- Lamination The SGP material must be bonded directly to the tin surface of the glass.

- For example: ATTAdirection (Glass air surface – glass tin surface/SGP film/Glass tin surface – glass air surface).

- Forglass that can not contact the film with a tin surface, such as multilayer laminated glass or glass produced by a non-float, use an adhesion accelerator on a non-tin surface, Please consult after-sales service for the formulation and use of adhesive accelerator.

3. Roll Compaction

- The temperature, pressure and speed selected for SGP film laminated glass are mainly the same as PVB film laminated glass. The heating temperature is lower and the speed is slower. The mechanical param- eter is as follows:

- 1. Preheating oven

- 2. Temperature of laminated glass surface is 20-25°C, humidity is about 25% oven 1 temperature: 100-110 °C, the pressure of the first big nip roller group is 0.2-0.5Mpa, The gap of big nip roller is ab less than the total thicknes 2 constant temperature is 130-140°C

- 3. The oven 3 constant temperature is 170-180°C

- 4. The pressure of the second big nip roce proup is 0.3-0.5MPa, and the ga roller is about 2mm less than the total thickness. In actual operation, the parameters can be adjusted according to the following instructions.

4. Evacuate Vacuum

- Vacuum pumping For more than two two layers of SGP film stacked together and sandwiched in the middle ddle of t of the glass, multi-layer structure of laminated glass, hot bent or bent steel laminated glass, large area of tempered laminated glass, etc, the vacuum bag process is appropriate.

- Especially for multi-layer glass structures with more than three layers of glass and two layers of film, do not use the rolling pre pressing process, but use the vacuum bag process. The cold extraction time is generally not less than 7 minutes, and preferably more than 10 minutes.

5. Autoclave Process

- It is a key process for laminated glass to enter the autoclave for high-temperature and high-pressure treatment. Controlling the temperature and pressure process of the autoclave is animportant factor in producing high-quality SGP laminated glass.

- 1. The spacing of laminated glass on the rack in the autoclave should not be too small, at least about 2cm; The local pressure on the glass should be minimized as much as insulin Uneven compression areas can cause uneven thickness of SGP fim during the heating process, sutting optical distortion. The angle of the glass on the rack should not exceed 10 degrees.

- 2. The insulation temperature shall be controlled between 125-135 C, the insulation time of SGP film laminated glass shall be more than 60 minutes, and the insulation time at 12-24ed glass with a thickness of more than 16 mm.

Product Specifications

FLS-EU SGP Film Specifications [Roll Materials]

Thickness

Width

Length

0.76mm

800mm-3660mm

200m

0.89mm

800mm-3660mm

200m

1.14mm

800mm-3660mm

150m

1.52mm

800mm-3660mm

100m

Note: Non-standard size can be customized

Technical Parameter

FLS-EU SGP Film and Ordinary PVB Film

Prüfgegenstand

FLS-EU SGP

Ordinary PVB

Prüfstandards

Specific Gravity g/cm

0.95

1.066

GB/T1033.1-2008

Tensile Strength MPa

34.5

28.1

GB/T1040.1-2018

Tear Strength KN/M

>120

10.0-20.0

GB/T1040.3-2006

Elongation at Break

400.0%

275.0%

GB/T1040.1-2018

Haze

<1.0%

2.0%

GB/T2680

Yellow Index

<1.5

6.0-12.0

GB/T2680

Refractive Index

1.5

1.47-1.50

GB/T2680

Transmittance

89.0%

89.0%

GB/T2680

Moisture Content

<0.2%

0.35%-0.65%

I.Z.B.

T.V. of Adhesive Force

≥7.0

≥6.0

GB/32020-2015

R.S. After Failurex

<10.0cm

/

I.Z.B.

T.V. - Tack Value

R.S. - Residual Strength

I.B.C.L - Ionic Intermediatemem Brane Cluster Labeling

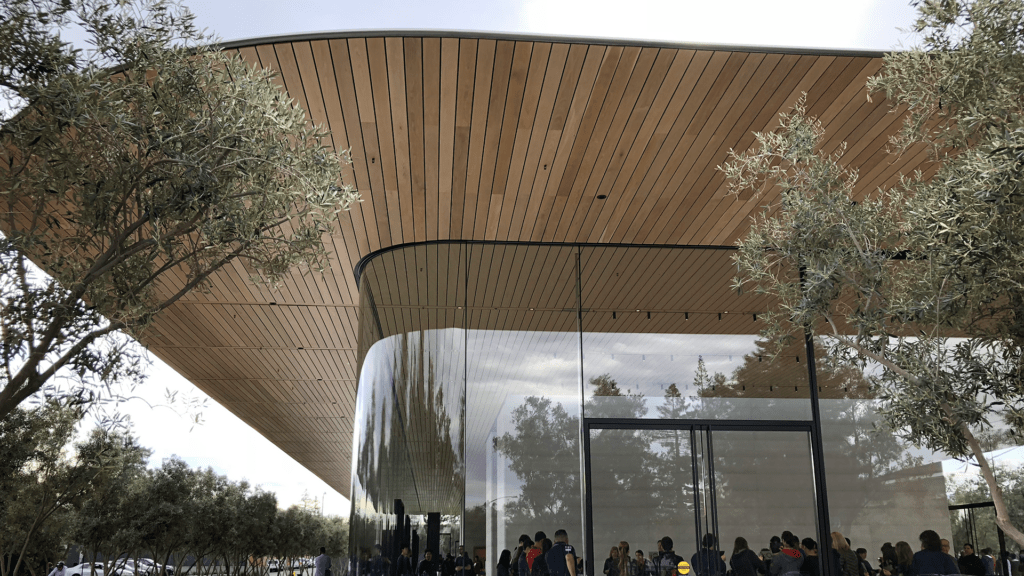

SGP Application Cases

Flughafen Hangzhou Xiaoshan

Used 1.52mm SGP film 23000 m2

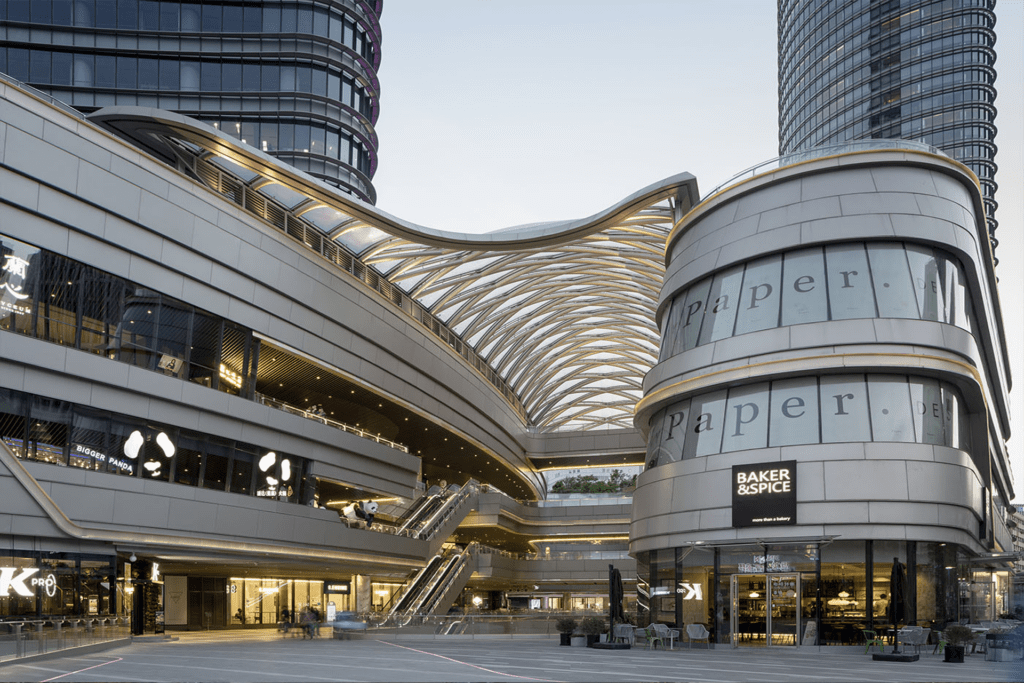

Shanghai Baiyulan Square

Used 0.89mm SGP film 36000 m2

Henglong Square, Kunming

Used 0.89mm SGP film 26000 m2

Jiangxi Glass Walkway

Used 1.52mm SGP film 9300 m2

Nanjing Shipping Building Proj.

Used 1.52mm SGP film 24000 m2

Hangzhou Shaw Hospital Proj.

Used 1.52mm SGP film 13000 m2

Shenzhen Bay 1# Proj.

Used 2.28mm SGP film 22000 m2

Pha. 3 Expansion Proj. of Airport

Used 1.52mm SGP film 22000 m2

Beijing SLX Glass Walkway proj.

Used 1.52mm SGP film 3600 m2

Contact

Chief Executive Officer

Mr. An Sun

Mettmanner Str. 51

40699 Erkrath

Deutschland

Phone: +49 176 845 868 46

Email:

an.sun@fls-eu.com

Sales Director

Ms. Dussling Jiang

Mettmanner Str. 51

40699 Erkrath

Deutschland

Phone: +49 157 378 581 25

Email:

xiao.jiang@fls-eu.com