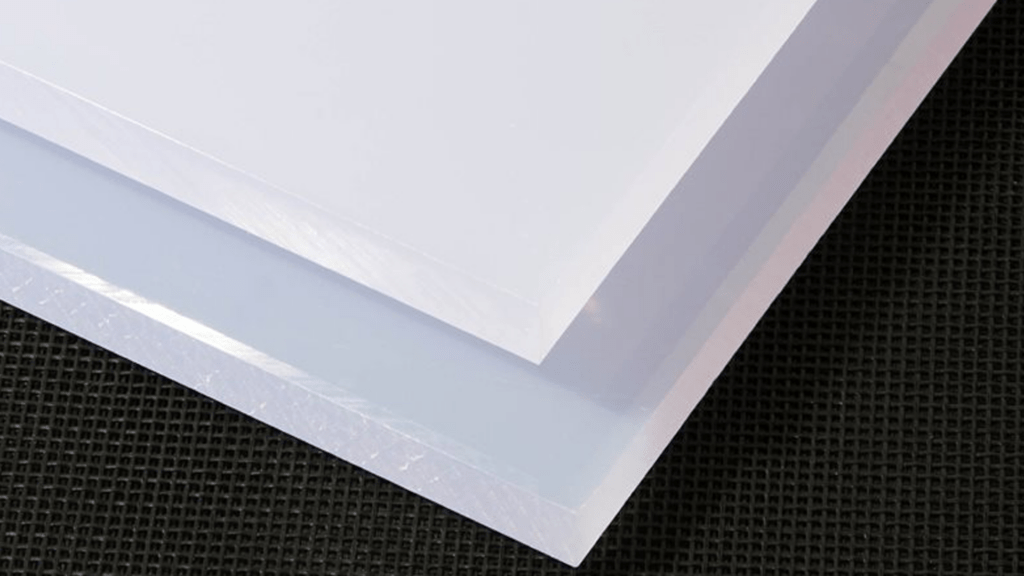

EVA

ETHYLENE-VINYL ACETATE

EAV FILM IS A KIND OF CAST FILM WHICH IS HIGHLY RESISTANT TO HARSH WEATHER CONDITION SND IMPACT WHENLAMINATED WITH GLASS.

Product Features And Advantages

*Excellent processing performance

- Has low density, making it lightweight and easy to handle and install.

- Easy to process and can be manufactured into various shapes using methods such as injection molding, extrusion, and blow molding.

- Possesses a certain level of elasticity and flexibility, making it suitable for manufacturing various bent or complex products.

*Exellent chemical properties

- It has excellent resistance to acid and alkali, oxidation, and corrosion. It can be used in various harsh environments and with a variety of media, such as oil, acids, alkalis, and more.

*Excellent Mechanical & PHY Properties

- After modification, its wear resistance is improved, allowing for prolonged use without cracking or aging.

- Its insulation performance is good, making it suitable for manufacturing various electronic product casings and insulation materials.

*Excellent Thermal Performance

- It can be bonded through heat and pressure, making it suitable for producing various composite materials.

- It has excellent thermal insulation performance, making it suitable for manufacturing products with high thermal insulation requirements, such as solar panel encapsulation, car seats, air conditioner covers, and more.

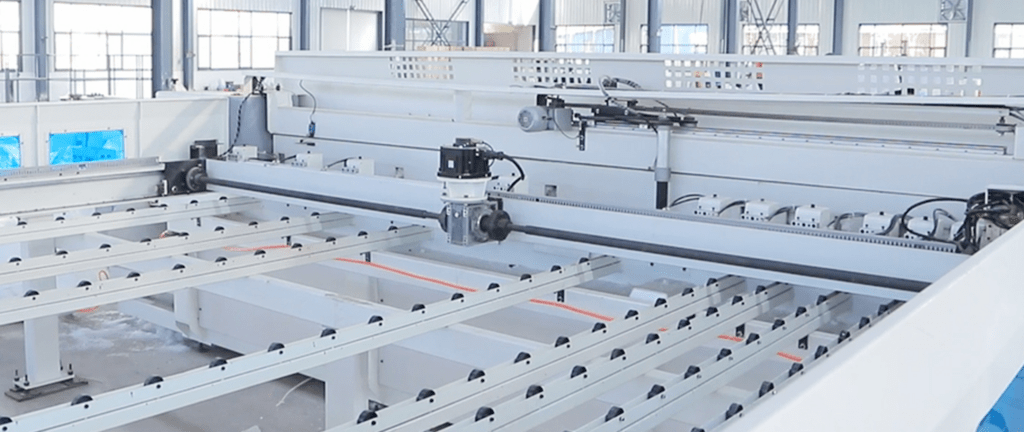

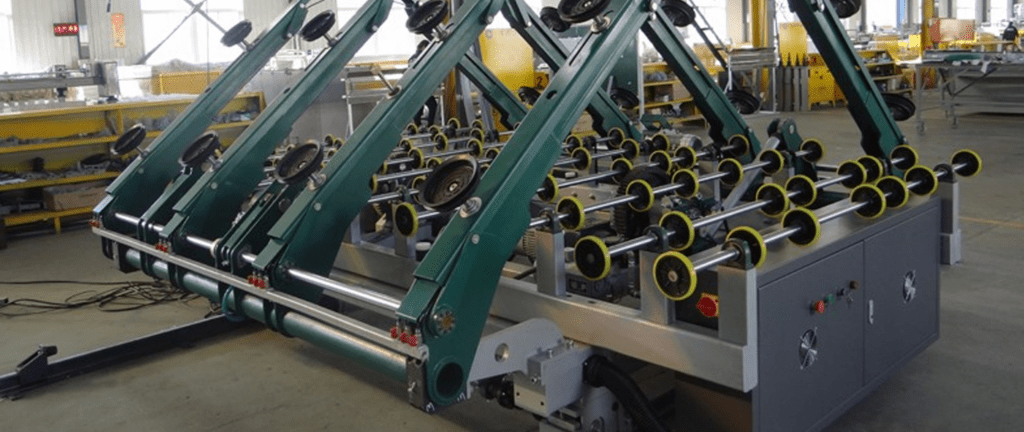

EVA Film Production Proces

1. De-Lamination

- The main reason is lamination temperature or temperature holding time is not enough. Check the temperature on glass surface and increase the temperature or pro-long the tempera- ture holding time.

- Moisture proof powder left on the glass surface, please clean the glass again. Fiber of paper or fabric laminated into the glass exposure outside is easily absorbed mois-ture when edging or stock, which results in de-lamination.

- We suggest the laminated material should be smaller than the film avoiding exposure. The UV printing & sealant may also cause some untoward effects when using with EVA film. More test need to be done before using!

2. Rime Fog

- Lamination temperature or temperature holding time is not enough, please re-operate again according to our operation procedure for only rime fog or cloud-fog.

3. Bubble

- Confirm vacuum pump working well, no leaking or blocked. Keep gas-channel and gas-guide hole unrestricted. Wooden stick, iron chain and wire mesh can be used for help gas guiding.

- Lower range temperature should not heating up more than 65 degree( glass surface tem- perature), because melting point of film is 70 degree. Or else, gas will be sealed in the laminat- ed glass, leading to bubbles.

- Air return: cool down under 60 degree, then turn off vacuum pump. Or else, air will return and result in bubbles around the edge.

- There will be bubbles because of not bounding strong caused by foreign matter on the glass surface.

- Tempered mark, thicker eva film should be used, because the surface is not flat.

- Unsuitable high temperature for lower temperature film, please decrease the lamination temperature by pro-long the temperature holding time.

Product Specifications

FLS-EU EVA Film Product Specifications

Thickness

Width

Length

0.25mm

2000mm

150m

0.38mm

2100mm

100m

0.76mm

2200mm

50m

1.14mm

2300mm

33m

1.52mm

2400mm

25m

Note: Other non-standard sizes can be customized according to customer requirements.

Technical Parameter

EVA Films Performance Parameter

Testing Item

Test Result

Testing Standards

Adhesive Power With Glass

>100N

BJ LAB TEST

VL Transmittance Rate

>91

BJ LAB TEST

Trübung

<0.3%

BJ LAB TEST

UV Resistance

>98%

BJ LAB TEST

Tensile Strength

20MPa

BJ LAB TEST

Cross-Linking

82%

BJ LAB TEST

Elongation At Break

560%

BJ LAB TEST

Water Aborption Rate

<0.1%

BJ LAB TEST

High Temp. Rsistance

Qualified

GB 15763-2009

Humidity Resistance

0.2

GB 15763-2009

Resistance to Radiation

Qualified

GB 15763-2009

Ball Impact Peeling Test

Qualified

GB 15763-2009

Shot-Bag Imapct Test

Qualified

GB 15763-2009

Shrinkage Rate - 60°C/15min

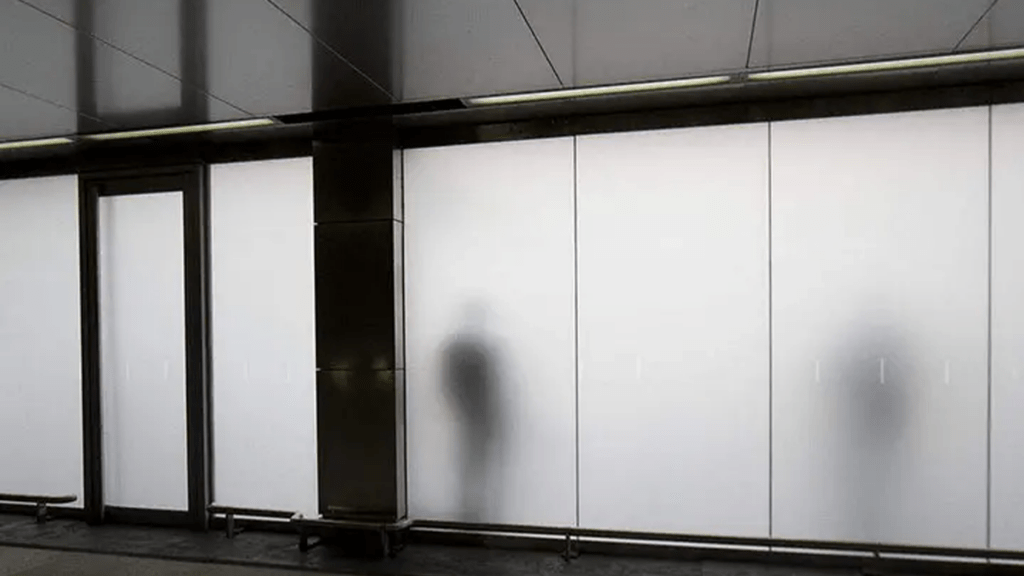

EVA Application Cases

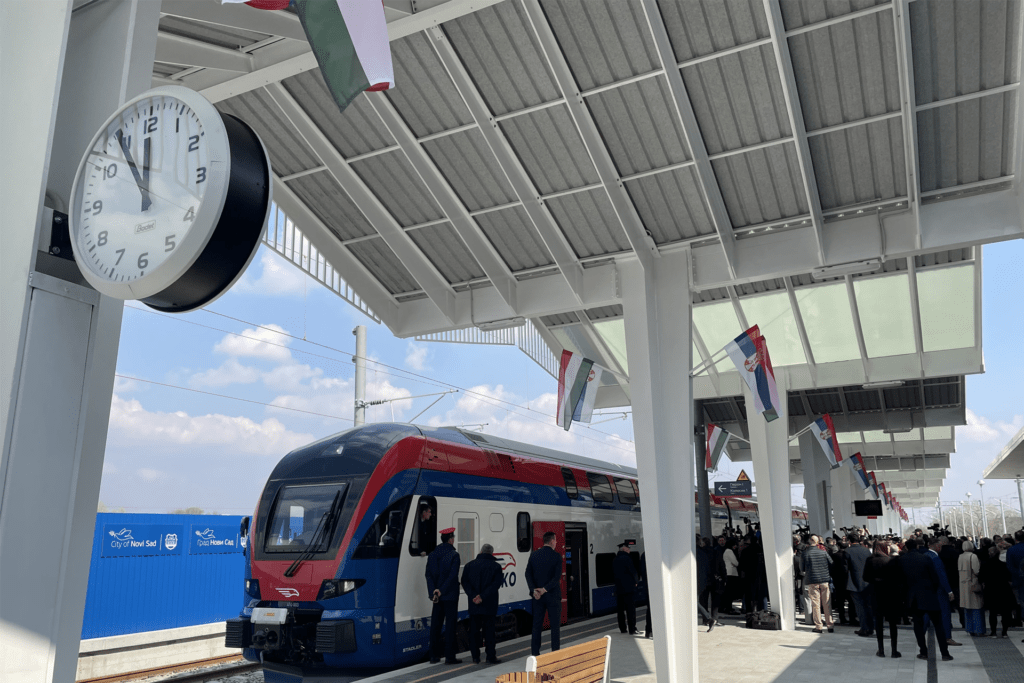

Hungary-Serbia Railway Proj.

Used EVA Film

BJ Sub. Ticket Hall Renovation Proj.

Used EVA Film

Oceanarium Tourist Tunnel

Used EVA Film

Kunming Shun Cheng Building

Used EVA Film

Qinhuangdao Residential Proj.

Used EVA Film

Overpass at SY Railway Station

Used EVA Film

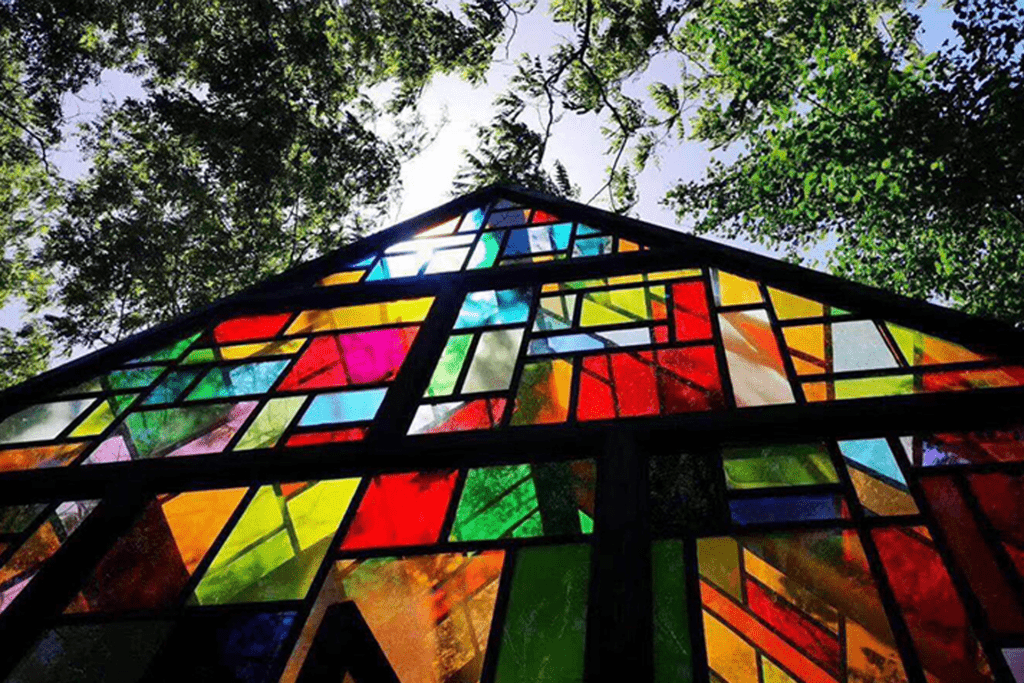

1.52 Outdoor U.C. EVA Film Glass

Used EVA Film

Color Film Production

Used EVA Film

Handan Sightseeing Elevator

Used EVA Film

Contact

Chief Executive Officer

Mr. An Sun

Mettmanner Str. 51

40699 Erkrath

Deutschland

Phone: +49 176 845 868 46

Email:

an.sun@fls-eu.com

Sales Director

Ms. Dussling Jiang

Mettmanner Str. 51

40699 Erkrath

Deutschland

Phone: +49 157 378 581 25

Email:

xiao.jiang@fls-eu.com